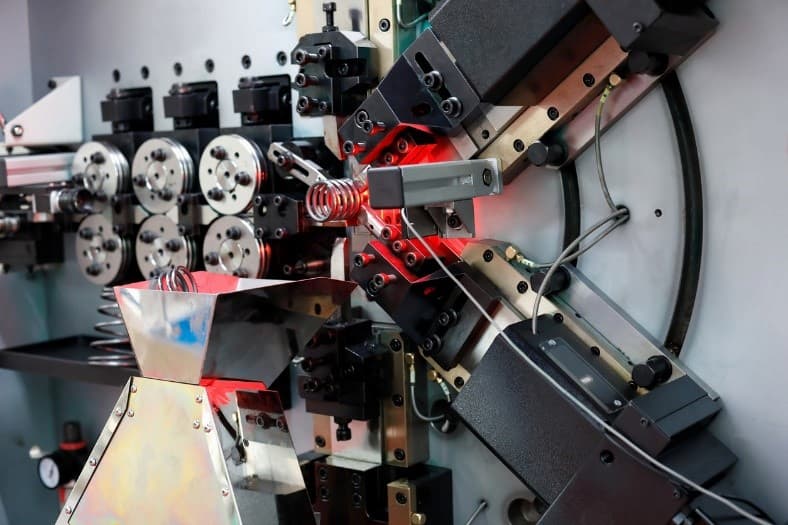

Robotic technology is certainly one of the most fascinating branches of electronics, constantly delivering advancements that we could only imagine or see in sci-fi films. As Industry 4.0 rapidly progresses, making automated processes a staple in manufacturing and nearly every other sector, technological innovations are in constant demand for components that will make complex developments easily achievable. Among these components, springs and pressings are versatile and adaptable enablers of robotic systems.

What are their applications? And how are they used efficiently to unlock new levels of mobility, control, and reliability, allowing automation to evolve? In this blog, we explore the different applications of springs and pressings in robotics, showcasing their important contribution to robotic technology.

Mobility in Robotic Systems: Mimicking Human Movements

Robots have become integral to an incredibly varied number of processes in many industries, whether used alone or paired with human workers. They are expected and required to tackle complex tasks with agility and precision and navigate challenging work environments with ease. Mobility and manoeuvrability are, understandably, a significant part of robotic systems, which are made possible by the contribution of both springs and pressings.

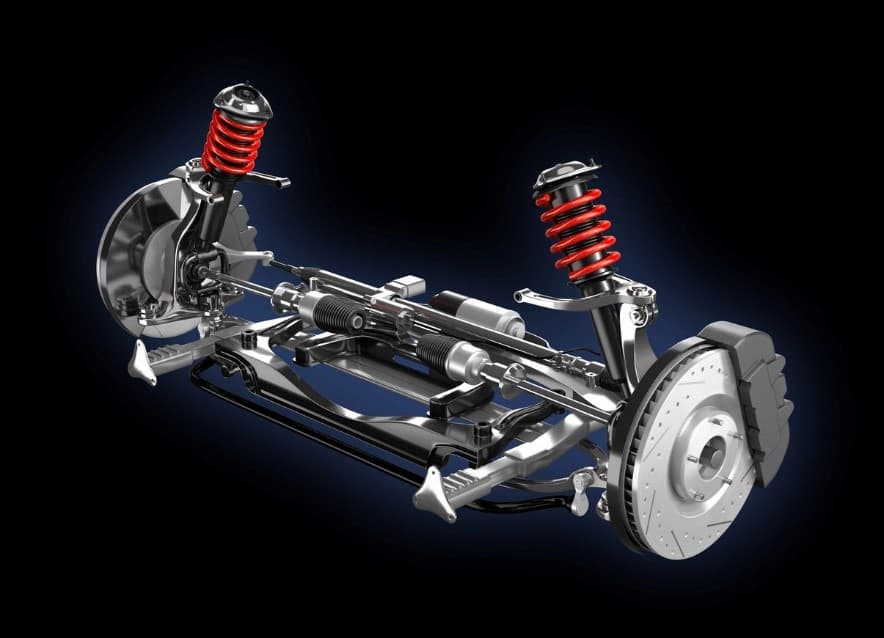

By incorporating spring-loaded joints and articulated mechanisms, robots successfully mimic some of the flexibility of human movements to interact with their environment easily. This allows them to move over uneven surfaces, overcome obstacles, and perform intricate tasks effortlessly. In addition, advancements in materials science have led to the development of lightweight and durable components, which make robots less heavy while maintaining their robustness. This not only improves these systems’ energy efficiency but also extends their operational capabilities, allowing them to work for longer periods without the need for frequent recharging or maintenance.

Enabling Precise Control, Handling, and Gripping

In activities that require delicate handling and precise control, such as assembly and pick-and-place operations, springs and pressings are major players in enabling accurate manipulation of objects. By employing compliant mechanisms and force-sensitive components, robots will automatically adapt and adjust their grip and exertion levels based on feedback from sensors, making sure their interaction with objects of varying shapes and sizes is gentle yet effective.

What’s more, springs’ natural flexibility allows for adaptive grasping strategies, granting robotic systems the ability to easily adjust to changes in the work environment and unexpected disruptions. This flexibility is particularly valuable in applications where the exact position and orientation of objects may vary, such as in warehouse automation and specific manufacturing processes. It is then safe to say that, as robotic systems continue to evolve, the integration of advanced metal pressings and springs in electronics will elevate their ability to perform challenging manipulation tasks with utmost precision and efficiency.

Springs and Pressings as Efficient Shock Absorbers

In dynamic environments such as industrial settings and outdoor operations, where shocks and vibrations are prevalent, compression springs and metal pressings act as efficient shock absorbers, mitigating the negative impact of such forces on robotic systems. By incorporating effective shock-absorbing mechanisms and vibration-damping materials, robots will benefit from improved stability and accuracy as well as enhanced reliability and durability, even in challenging working conditions or demanding environments.

For example, in mobile robotics applications such as drones and crewless ground vehicles, custom springs help absorb the vibrations generated by uneven terrain or high-speed movement, ensuring continuous and stable operation. Similarly, in industrial automation, the use of compliant joints and damping parts helps reduce wear and tear on robotic components, extending their lifespan and reducing maintenance costs.

Low-Friction and Lightweight Materials to Improve Energy Efficiency

Energy efficiency is a critical consideration in robotics, especially in applications where power constraints or limited battery life are relevant concerns. Here, springs and pressings improve energy efficiency by minimising frictional losses, optimising mechanical design, and reducing the overall power consumption of robotic systems.

For instance, by employing lightweight and low-friction materials in spring-loaded mechanisms, robots achieve smoother and more efficient motion, requiring less energy to function. In addition, the use of compliant structures and elastic elements allows for energy storage and release so that robots can use kinetic energy during movement and reduce reliance on external power sources.

Boosting Resilience in Robots’ Structural Integrity

The structural integrity of robotic systems is essential to their safe and effective functioning in terms of reliability and performance. In this regard, springs and pressings emerge as critical components, offering invaluable support and strength against external forces. Whether it’s guaranteeing stability during complex manoeuvres or withstanding impacts in demanding environments, these components provide the necessary resilience to maintain the integrity of robotic structures as healthy and performative as possible.

In collaborative robotics scenarios, where humans and robots share workspaces, the importance of structural integrity is even higher. Here, compliant joints and impact-absorbing materials serve as indispensable safeguards to minimise the risk of injury in the event of accidental collisions or contact. In industrial automation, where precision and reliability are non-negotiable, robust pressings bolster the structural stability of robots. Such reinforcement enables these systems to execute any task with precision and repeatability, even under heavy loads, ensuring uninterrupted operation in manufacturing environments. Overall, springs and pressings help with robots’ physical longevity and increase your confidence in their safe and efficient performance across various applications.

Stay at the Forefront of Technological Progress with European Springs

As we learnt, in robotics, where innovation never stops to drive progress, springs and pressings relentlessly are more vital than ever for elevating designs and projects to new heights of efficiency and performance.

Whether you’re an engineer pushing the boundaries of automation or a business specialising in robotics, at European Springs, we stand ready to support your visions and projects. With a reputation for excellence and a commitment to top-tier quality, we offer a range of precision-engineered springs and pressings tailored to meet the incredibly specific needs of the robotics industry.

Browse our springs catalogue and contact us today to discover how our products help you achieve your objectives and stay ahead of technological advancement.

Sustainability has become the world’s foremost concern, encompassing every industry and a wide variety of practices. With this heightened attention, global and local businesses alike are seeking innovative solutions to align with eco-consciousness. Here, Enterprise Resource Planning (ERP) systems, initially designed to streamline operations and boost efficiency, are essential tools for improving sustainability within manufacturing. By using ERPs, manufacturers can easily optimise resource allocation, minimise waste, and reduce their environmental impact.

Sustainability has become the world’s foremost concern, encompassing every industry and a wide variety of practices. With this heightened attention, global and local businesses alike are seeking innovative solutions to align with eco-consciousness. Here, Enterprise Resource Planning (ERP) systems, initially designed to streamline operations and boost efficiency, are essential tools for improving sustainability within manufacturing. By using ERPs, manufacturers can easily optimise resource allocation, minimise waste, and reduce their environmental impact.

Hydroelectric power stations stand tall as marvels of engineering, using the force of flowing water to generate sustainable energy. From dampening vibrations in turbines to enabling precise power regulation in control systems, various springs work together to allow these energy giants to work efficiently, supporting a number of industries in their goal of moving towards a greener future.

Hydroelectric power stations stand tall as marvels of engineering, using the force of flowing water to generate sustainable energy. From dampening vibrations in turbines to enabling precise power regulation in control systems, various springs work together to allow these energy giants to work efficiently, supporting a number of industries in their goal of moving towards a greener future.