Components in the clean energy sector play a crucial role in shaping a more sustainable future for power generation. Springs and pressings, for example, are essential in various clean energy applications, including wind turbines and solar panels.

As experienced spring manufacturers, we continuously develop spring solutions for a wide range of industries, including clean energy. Keep reading to discover the vital role springs play in this sector, along with examples of their applications and different spring types.

Spring and Pressing Manufacturing for Clean Energy

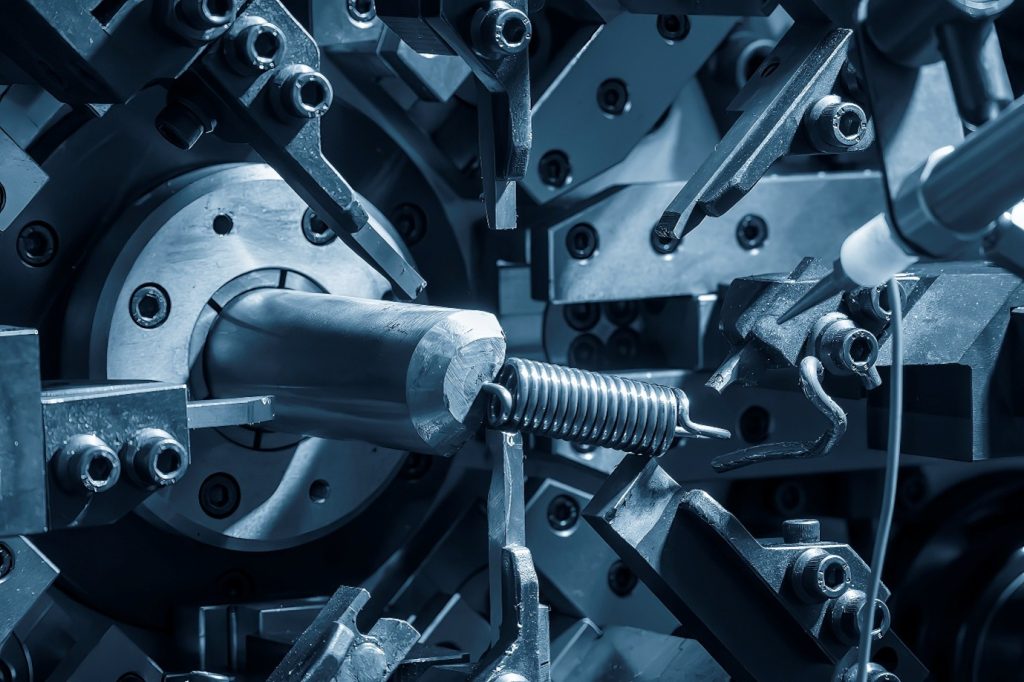

When it comes to this industry, spring manufacturers need to be constantly innovating the ways in which they create springs to keep up with the ever-evolving capabilities of renewable energy. This not only means developing manufacturing techniques adapted to the clean energy sphere but also making sure that testing processes are thorough and refined.

Springs and pressings in this industry benefit from surface treatments and coatings, especially if they are subject to harsh conditions like hydroelectric components. Elements like high winds, saltwater corrosion, or the extreme temperatures found in solar power installations can impact the longevity of a component over time. Surface treatments like plating, heat treatment, barrelling, and de-burring are just some examples of how springs and pressings can be made to last longer in these intense environments.

When designing springs for renewable energy purposes, manufacturers need to take into account factors like fluctuating loads, accounting for potential energy loss, and exposure to harsh environmental conditions. We implement state-of-the-art manufacturing processes that allow us to create reliable springs and pressings for the clean energy sector and are always looking to improve our operations to be more efficient and effective.

Applications of Springs and Pressings in Renewable Energy

Springs and pressings have a variety of applications within the renewable energy space and are designed to withstand the high demand these environments impose. Here just a few examples of where springs and pressings exist in the clean energy sector:

Wind Turbines

Wind turbines are an essential form of renewable energy, harnessing the power of natural wind to form a more sustainable energy solution. Turbines are often exposed to high wind speeds, which increase blade rotations and have a potential impact on safety and energy efficiency. Pitch-control systems are implemented to handle these high-speed winds, and spring-loaded mechanisms are found in this part of the turbine.

When experiencing regular wind conditions, springs maintain the blade angle in the correct position and if speeds begin to rise, springs adjust their position by either tightening or loosening. Not all springs built for this purpose will be designed in the same way, as manufacturers consider specific wind conditions and turbine specifications to make the spring as effective as possible. In areas with changing wind patterns, springs in wind turbines may need more motion flexibility in comparison to areas with consistent wind patterns.

Metal pressings are used in the production of parts for wind turbines, including in brackets, housings, and mounting frames. These parts need to be strong and lightweight, and metal pressing uses precise technology to shape materials to fit the specific design of the turbine.

Solar Panels

Solar panels are mechanisms that allow energy to be derived from the sun’s radiation, found in both commercial and domestic applications. Springs and pressings are found in a number of areas within solar panels, like in the solar trackers, which help the solar panels to be placed in the best orientation for sunlight exposure.

As the sun’s path moves throughout the day, solar trackers rely on springs to manage the tilt and rotation of a solar panel so that it can face the sun directly. This continual adjustment feature captures more sunlight, which results in higher energy efficiency. Moreover, when there is a low energy supply, springs can still work effectively using energy stored from active periods.

In terms of pressings, the frames that hold solar panels in place are often made using metal pressings. These frames need to be durable and weather-resistant, and the mass productions of pressings allow for these components to be made in the same shape and size.

Types of Springs Used in the Renewable Sector

A variety of spring types are found in the renewable sector. For instance, torsion springs are used in the control systems of hydroelectric power mechanisms as their torque capabilities make them adapted to providing precise adjustments for accurate and smooth operation.

Compression springs are found in a number of sustainable energy applications, such as within large-scale solar farms, within the pitch-control mechanism of wind turbines, and as shock absorbers for the turbine assemblies of hydroelectric power systems.

Additionally, tension springs are often favoured for their ability to be constructed in a smaller size, so they’re perfect for residential solar systems that contain lighter panels. They also help to assist in regulating the speed of turbines because of their ability to stretch and return to their original state, creating necessary tension that makes the turbine operate at a steady rotational speed.

Springs and pressings are essential components in the clean energy sector, enabling the efficiency and durability of renewable energy systems like wind turbines, solar panels, and hydroelectric power mechanisms. As innovation continues to drive the renewable energy industry forward, the role of springs and pressings will only become more integral to a clean energy future. To learn more about the components we design and manufacture, please feel free to get in touch.