Tackling the Manufacturing Talent Shortage

As experienced spring manufacturers, we recognise significant changes within our industry following the Covid-19 pandemic that have affected the in-demand

Home › News & Updates › Page 8

As experienced spring manufacturers, we recognise significant changes within our industry following the Covid-19 pandemic that have affected the in-demand

After a year and a half of Covid restrictions, the DSEI 2021 show was the first exhibition that European Springs

European Springs & Pressings and Metrol attended the recent DSEI Expo at Excel London for the first time, sharing an

As an experienced spring manufacturer, we see many uses for our springs throughout the agricultural industry. Our high-quality springs are

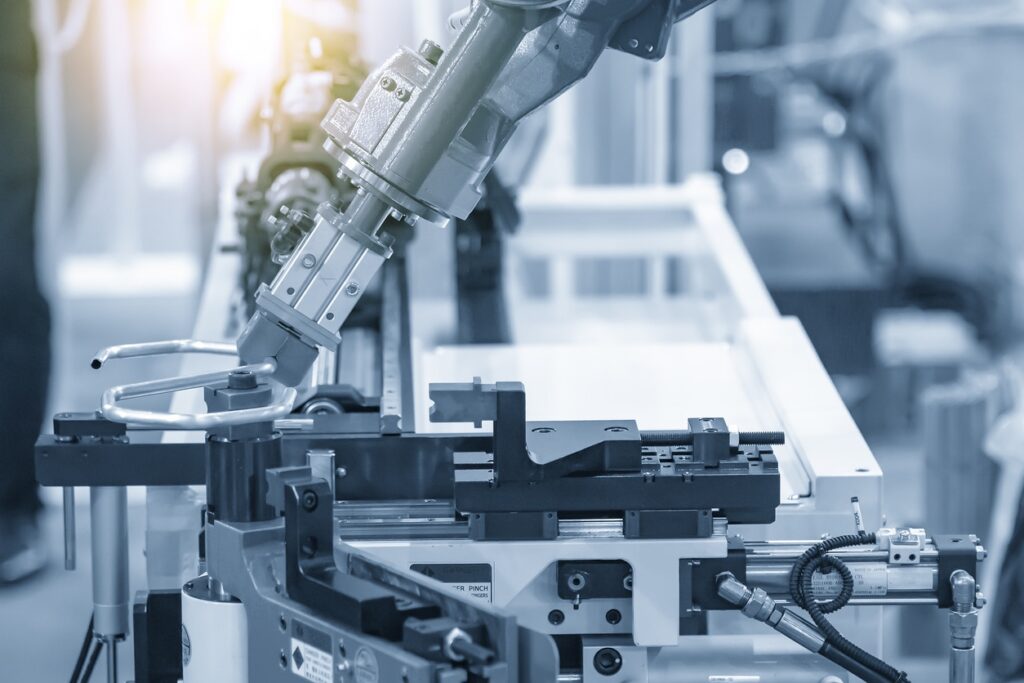

We’re proud to be industry leaders in spring manufacturing, and being at the forefront of the current technological revolution is

As an industry leader in spring manufacturing, automation plays an important part in the process that continues to advance the

UK manufacturing is set to double in growth throughout 2021 following an unpredicted rebound in production. Many manufacturers have invested

As leading spring manufacturers, we keep our fingers on the pulse with everything going on in the manufacturing and engineering

As spring manufacturers, we must keep up with the latest news, movements and events within our industry. We’re delighted to

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital