Ground, Sea and Air Defence Supporting With Military-Grade Springs

For any machine application, meeting the required design specifications and ensuring component reliability is crucial, and there are few sectors

Home › Engineering › Page 4

For any machine application, meeting the required design specifications and ensuring component reliability is crucial, and there are few sectors

The collaboration between manufacturers and energy companies is consistently beneficial, and this is especially relevant when considering the engineering possibilities

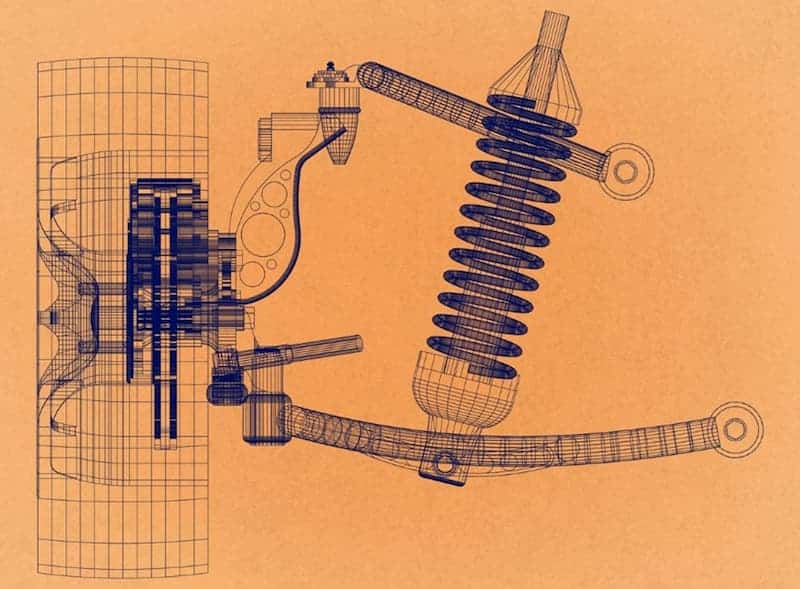

Springs are essential components within almost every application, from commercial products to industrial machinery and transport. The unique requirements of

At European Springs, we take great pride in our expertise in designing and manufacturing various spring and pressing products for

Today, the demand for space-efficient designs has witnessed a significant increase. As more people embrace minimalistic living and seek to

The pinnacle of motorsport, Formula 1, is globally recognised for its constant technological advancements. For drivers, securing top speed is

At European Springs, we take pride in being a leading spring manufacturer and supplier, providing bespoke springs, pressings, and wire

In our fast-paced global economy, manufacturing companies are continuously searching for ways to enhance their operations, streamline their processes, and

At European Springs, we are at the forefront of the dynamic spring manufacturing field, empowered by our cutting-edge CNC machinery

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital