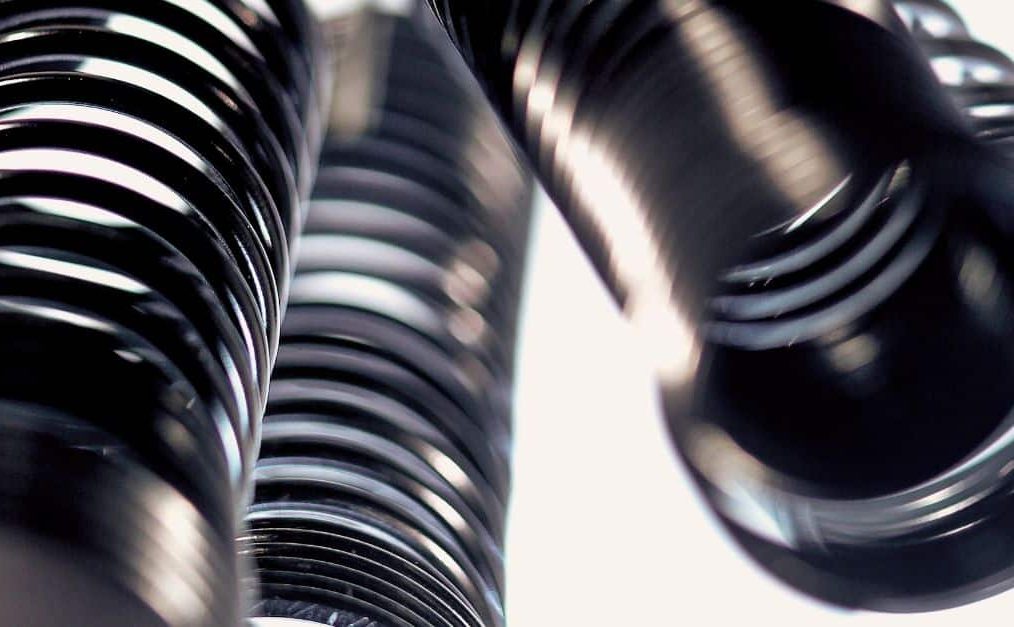

We manufacture springs for a range of industries, from automotive to aerospace and medical devices. But what materials are used by spring manufacturers to construct these components?

The shorter answer: steel alloys are the most common, due to their strength, durability, and versatility. However, different projects require different metals.

In this guide, we’ll explore the most widely used spring materials, their properties, and where they find a purpose.

Common Materials for Springs

Most springs are made from one of the following:

- Low-Alloy Steel

- Cold Formed Steel

- Oil Tempered

- Bainitic Hardened Steel

- Stainless Steel

- Copper & Titanium Alloys

Each offers distinct properties, from high-temperature resistance to corrosion protection, making material choice a key part of the manufacturing process.

Low-Alloy Steel

Low alloy steels are ferrous metals often considered superior to carbon steels in many ways, though it always depends on the intended use. Low-alloy steels are created by adding other elements such as nickel, chromium or molybdenum.

Benefits for springs include:

- Very high-temperature properties (hot compressive strength)

- Strong resistance to axial stress

- Improved creep strength

This makes low-alloy steel suitable for high-load springs used in industrial machinery.

Cold Drawn Wire

Cold drawing is a type of work hardening that changes the basic crystalline structure of steel, altering its properties.

Why it matters for springs:

- Greater tensile strength.

- High tolerance for stress and heat.

- Smooth surface finish for precise performance.

As spring manufacturers, we apply a variety of techniques to create wire forms for different qualities and capabilities. From die springs to tension springs, we’re experts in designing components that last.

Oil Tempered Spring Wire

Oil-tempered spring wire is used in everyday applications and has several mini categories which define the properties of the wire, including its fatigue stress properties.

Advantages include:

- Reliability where suspension is integral to the device’s functionality.

- Excellent fatigue stress resistance.

- Suitability for the automotive industry.

Bainite Hardened Strip

Bainitic steels undergo a heat treatment process, resulting in higher fatigue resistance and durability compared to martensitic steels.

Why manufacturers prefer it:

- Greater strength without additional heat treatment.

- Metal flexibility for manufacturing complex parts.

- High wear resistance.

Stainless spring steel

Stainless steels are created by raising the amount of chromium in the steel (10%-17%). Spring-tempered steels also include around 7% nickel, some magnesium and even carbon.

The high concentration of chromium in this steel is what provides protection against oxidisation and some organic acids. The nickel used in this metal protects against reducing atmospheres and acids such as phosphoric.

Key Benefits:

- Fantastic yield strength.

- Protection against corrosion.

- High temperature resistance.

Stainless spring steel is used in a range of applications such as washers, lock picks, antennae and, of course, springs. Many stainless steel components are created through cold working temperatures, due to their inability to be hot worked below 1700°F. This can cause magnetism in the material, which we treat after the form is cast.

Copper and Titanium Alloys

While less common than steel, copper and titanium alloys play a significant role where precision and corrosion resistance are priorities:

Titanium alloys:

- Lightweight yet strong.

- High fatigue resistance.

- Used in aerospace, military aircraft, and medical devices.

Copper alloys

- Used by torsion spring manufacturers.

- Excellent thermal and electrical conductivity.

- Variations like beryllium copper have a high tensile strength and hardness.

- Phosphor bronze, another important copper alloy, is valued for its excellent fatigue and wear resistance, and ability to perform reliably in corrosive environments.

High-Performance Superalloys

For extreme environments where standard steels are not suitable, we use superalloys like Hastelloy, Inconel, Nimonic, and Elgiloy. These nickel and cobalt alloys have excellent corrosion resistance, fatigue strength, and high-temperature stability, making them adapted for a range of applications.

Why choose superalloy materials:

- Hastelloy: resists oxidisation and aggressive chemicals, popular in chemical plants and marine engineering.

- Inconel: keeps its strength at elevated temperatures and under heavy stress, widely used in aerospace and energy.

- Nimonic: offers superb creep resistance and thermal stability, commonly found in gas turbines and power generation.

- Elgiloy: provides high strength and is not magnetic, often used in medical devices and aerospace.

These alloys can be more costly than standard steels but are chosen when reliability under extreme heat or corrosion is non-negotiable.

Why Material Choice Matters for Your Project

Springs and wire forms have many important uses in daily applications, so using high-quality materials is critical.

At European Springs & Pressings, we are experienced spring manufacturers that craft compression springs, torsion springs, and wire forms, using only the highest-quality materials.

Need custom springs for your project? Request a quote with our friendly team of experts – we’ll help you choose the perfect spring material for your application.