Metal pressing is a versatile and essential manufacturing process that transforms flat metal sheets into precise components. This complex process involves various metal-forming techniques and serves industries worldwide. As global markets demand increasingly intricate parts with faster turnaround times, manufacturers face significant challenges in maintaining quality and efficiency.

One of the primary difficulties in metal pressing arises from the material itself. Metals can crack or deform during stamping due to excessive strain, improper material selection, inadequate cutting tools, flawed mould design, incorrect stamping settings, or insufficient lubrication. Addressing these issues requires expertise, precision, and advanced technology.

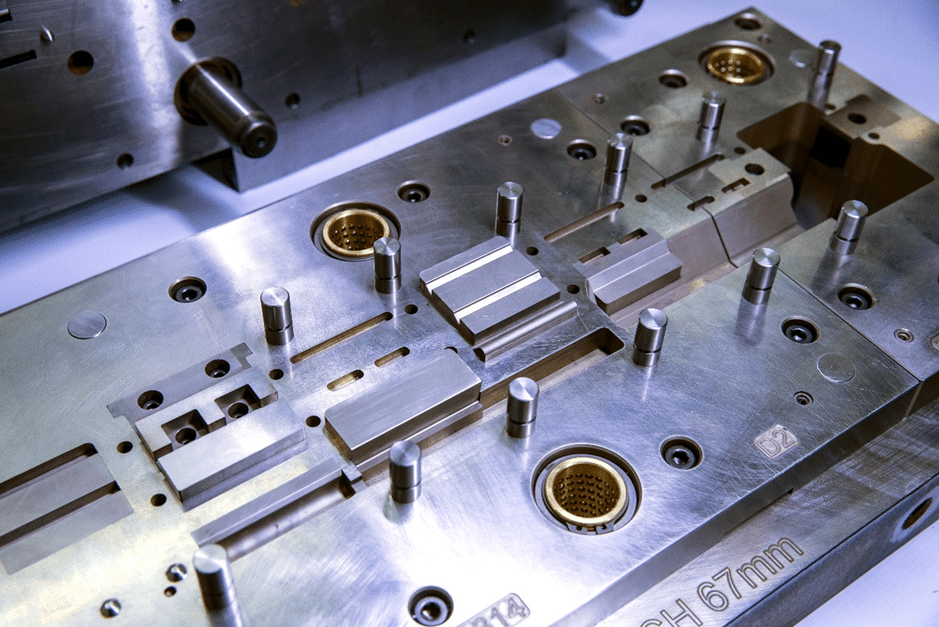

The stamping process begins with placing sheet metal, either in coil or blank form, into a machine that applies controlled force and pressure. Specialised tooling, known as dies, is then used to shape the metal through various stamping operations, ensuring accuracy and consistency.

We excel in overcoming these challenges by implementing cutting-edge technologies and tailored solutions to deliver exceptional results.

Material Inconsistencies

In metal stamping, improper material selection is a frequent issue. If the incorrect material is utilised for a certain stamping job, poor quality stamping and other issues might occur. The differences in thickness, hardness, and other characteristics of the metal significantly affect the process of stamping. Straining, creasing, and cracking caused by such inconsistencies reduce the quality and appearance of the part. The selection of the right material for every operation is necessary to prevent stamping issues as a result of an incorrect material selection.

This involves considering factors like the use of the metal part, what properties it has and the cost of the material. We work very closely alongside our clients to make sure we understand your needs and requirements before creating anything so that we can select the correct material for a specific project. We also constantly test materials to identify inconsistencies and make sure that the material used is of the highest quality. Our goal is to ensure a smooth stamping process with excellent results.

Tooling Wear and Tear

The friction formed when the sheet metal interacts with the tooling surface is what leads to ‘tool and die wear’. Damage to the die surface results in material loss in the tooling, which damages the metal sheet surface and leads to failure and faults including burrs, misalignments, and poor stamping. Tool wear can also reduce the accuracy of cuts and shapes, which affects the overall product’s precision. You can do a few things to prevent tool wear, including regular maintenance. Ensure tools are lubricated as it reduces friction and wear.

It is essential to choose the right type of lubricant based on the material that is being stamped on the tool’s specification. Cleaning the tools also helps minimise tear and wear as it removes excess debris and dirt that can cause wear and corrosion. At European Springs, we utilise advanced tooling materials and technologies to withstand the pressure of high-volume production. On top of that, our team also constantly performs regular maintenance on all equipment to make sure all tools are kept in top condition throughout the production process. This proactive approach not only prolongs the life of the tooling but also prevents defects caused by tool wear.

Residual Stresses and Spring back in Metal Pressing

Residual stress and spring back are common occurrences during metal pressings. Stress occurs due to the elastic recovery of the material after plastic deformation during forming, which can cause pressure and stress even once the load has been removed. Spring back is a particularly challenging issue when working with materials like steel or aluminium, which tend to return to their original shape after being bent or stamped. The sheet material, production factors, and achieving necessary measurement and form are some of the variables that influence it.

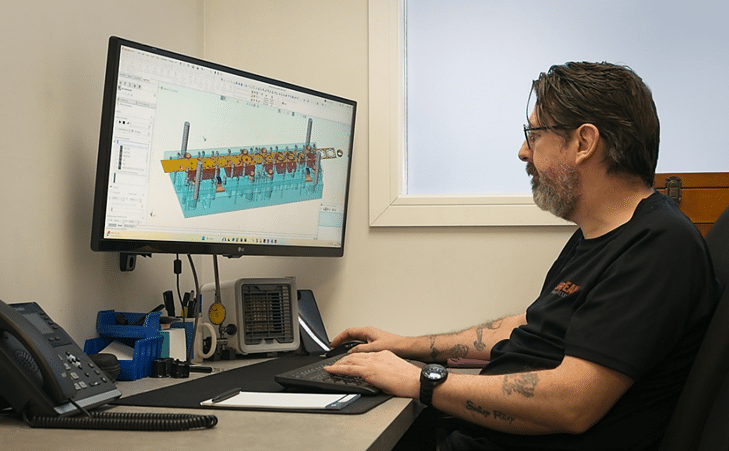

These issues can lead to distorted parts, poor fit, and inconsistencies in dimensions. To reduce these residual stresses and spring back, European Springs utilises an advanced engineering design process and simulation tools. Using computer-aided design (CAD) and 3D rendering software, we can address any problem that may occur and prevent it before the stamping process begins. This allows engineers to adjust tooling and materials to achieve the desired outcome, guaranteeing the highest quality products.

High-Volume Production Challenges

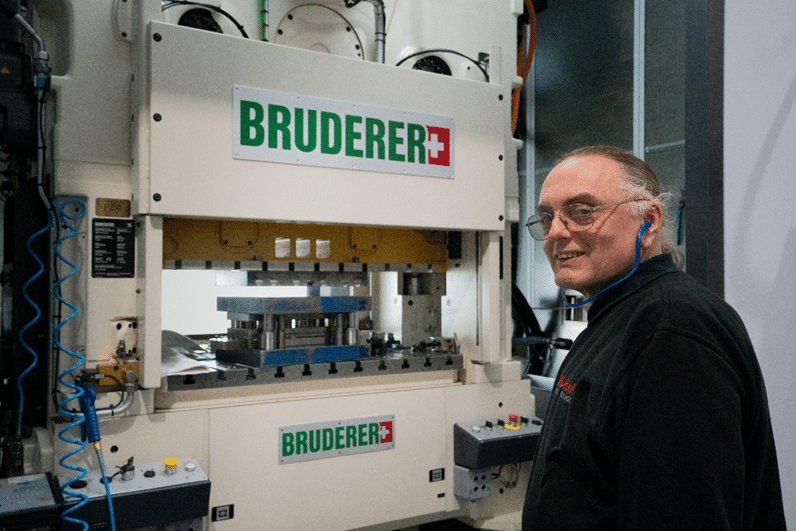

High-volume metal stamping is the process of producing large quantities of complex metal parts with high speed and efficiency. The method utilises highly specialised equipment to form metal sheets into precise shapes. High-volume metal stamping is unavoidable in industrial fields like aerospace and electronics, where precision and volume are of top priority.

Maintaining quality during high-volume metal stamping is challenging due to the difficulty of achieving consistent deformation and complex shapes and the need for robust quality control and inspection processes. Tool wear and material variations become more noticeable, which can result in inconsistencies between parts.

European Springs and Pressings combats these problems through automation, real-time monitoring, and regular upkeep. We monitor and examine real-time data throughout the manufacturing process to spot potential issues before they happen lowering downtime and raising performance, our automated solutions provide a consistent stamping process. Regardless of the amount, these procedures ensure that each component is of the highest standard.

Preventive Measures and Solutions

Preventing common pressing challenges is important to providing a smooth stamping process. As mentioned previously, the selection of appropriate tools, materials, and coatings, along with preventive measures like regular maintenance, can lead to success.

Our skilled team conducts regular maintenance on all the tools and machines used during the stamping process to ensure they are in perfect condition for the next project. To enhance the quality of our results, we have also made investments in excellent machinery and resources. Thorough testing methods are implemented to identify potential issues. Taking these measures can help reduce the challenges encountered with metal pressings.

Metal stamping is an efficient manufacturing process; however, it presents a range of challenges, as mentioned above. Quality control is crucial, and we provide the expertise and tools necessary to tackle these challenges. Using advanced tools, detailed processes and bespoke solutions, we guarantee that every project is completed to the highest standards of quality.

If you’re wondering how we can help with your metal pressing challenges, don’t hesitate to get in touch with our team. We can work with you to provide solutions that help achieve excellent results.