We’re proud to manufacture precision springs and pressings for a variety of sectors. For the medical industry, our springs and pressings are used in a wide range of applications, from supporting components to performing essential mechanical functions at the heart of critical medical devices.

Though often hidden from view, these precision-engineered parts are vital to the performance, safety, and reliability of advanced medical technologies, including diagnostic imaging systems and life-saving implantable devices.

Pacemakers: Compression Springs for Heartbeat Regulation

Pacemakers are an electronic device that are implanted into the body to treat irregular or abnormal heart rhythms. The pacemaker sends electrical pulses to the heart, helping it to beat at a regular and healthy rate.

Inside these devices, compression springs are used to secure the leads that connect electronic circuitry to the heart muscle. Due to the nature of pacemakers being placed inside the body, we use select biocompatible materials like stainless steel. Using metals like these minimise the potential for allergic reactions or tissue irritation in the body, and their corrosion resistance makes them ideal for resisting body fluids or tissue over extended periods.

Pressings in Surgical and Diagnostic Equipment

Pressings and metal stampings share an equally important role in medical devices as springs. There are a number of areas where you may find a pressing within medical devices including:

- Surgical Instruments: Tools such as drills, retractors, and drills utilise pressings made from surgical-grade materials.

- Medical Device Housing or Enclosures: Pressings are located in the enclosures or casings of medical devices, securing them away from potential damage or contamination.

- Implantable Devices: Like springs, pressings can also be found in devices like pacemakers.

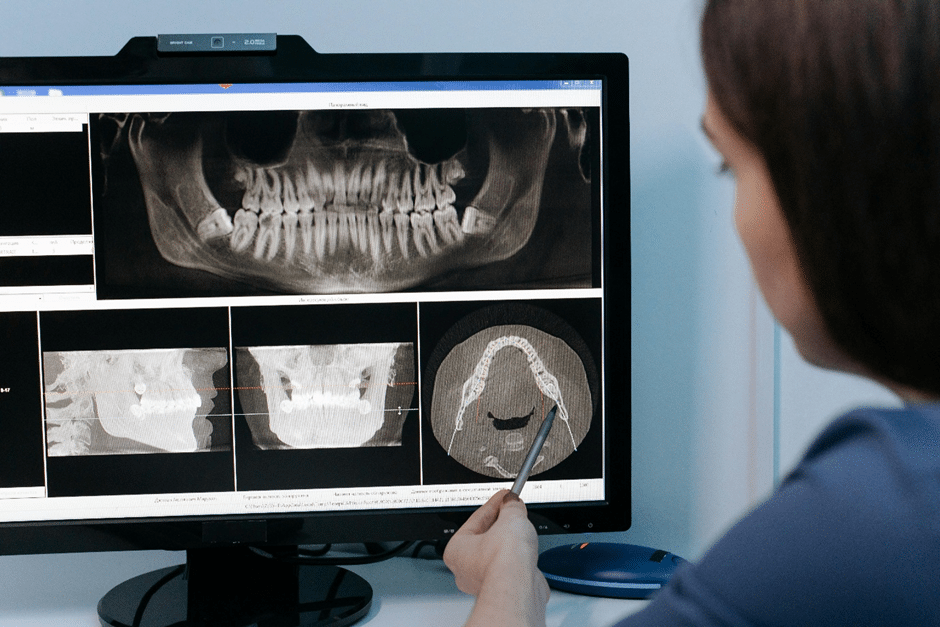

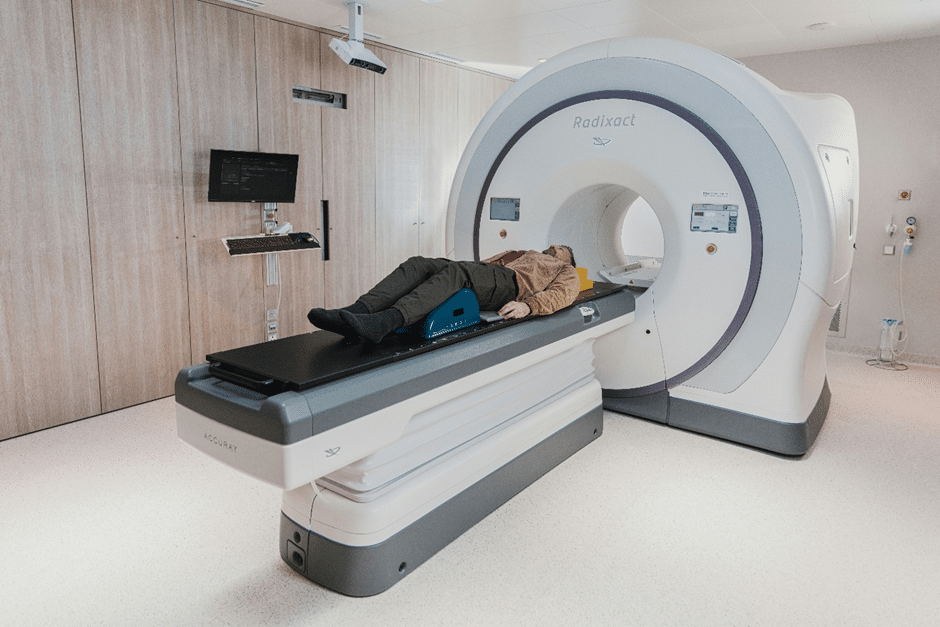

- Imaging and Diagnostic Equipment: Equipment like MRI, CT, X-ray, and ultrasound scanners utilise metal pressings.

Our custom metal stamping service ensures you get tailored solutions that meet stringent medical regulatory standards. We work with a range of high-performance alloys, delivering components with consistent quality and traceability.

Diagnostic and Imaging Devices

As we’ve outlined, pressings are used in machines that providing imaging or diagnostic services – but springs play an integral role here, too. These machines often need to be able turn and move with ease, to work around different patient needs. This application benefits from using torsion springs, as these components provide rotational movement due to the torque exerted when pushed in different directions.

Dental X-ray units are a prime example where the rotational capabilities of torsion springs are best utilised, as these units have to be positioned precisely to capture images of a small area of the body. Similarly, gas springs help in medical applications across the board, including in hospital beds, due to their ability to make certain mechanisms adjustable. This applies to CT scanners, where gas springs are implemented to create more accurate and adjustable diagnoses.

Drug Delivery Devices

Drug delivery devices are commonly used within the medical sector, whether it’s within a hospital environment or for everyday use. Springs are used because these devices often need to provide specific amounts of force precisely in controlled tolerances, to ensure the users isn’t given too much or too little of their required drug. It is vital that springs provide consistent levels of actuation force over time, so that the device does not wear or decrease in performance.

In inhalers, compression springs store mechanical energy when they’re compressed, and upon release, they exert force that pumps the medication through the inhaler and into the user’s mouth. Inhalers are used on a daily basis by millions of people, highlighting the importance of springs both within advanced, technical medical devices and daily essentials. Similarly, compression springs are found in insulin pens, auto-injectors, and syringes to ensure an equally reliable and precise dose of medication.

Why Quality Matters in Medical Springs and Pressings

When developing components for critical medical applications, choosing the right manufacturing partner is essential. We work closely with clients to design and deliver components that are:

- Manufactured from certified, medical-grade materials

- Produced to meet regulatory compliance (e.g., ISO 13485)

- Tested for durability, repeatability, and biocompatibility

- Custom-made to meet your device’s unique specifications

Explore our full range of made-to-order springs or contact us today to discuss your bespoke requirements for medical applications.