Flat Springs are utilised in many different industries and applications, and they thrive in areas where space is limited because of their compact design. In this blog, we will cover the diverse uses of flat springs, their unique design, how they are used in a variety of different ways, and things to consider before purchasing flat springs.

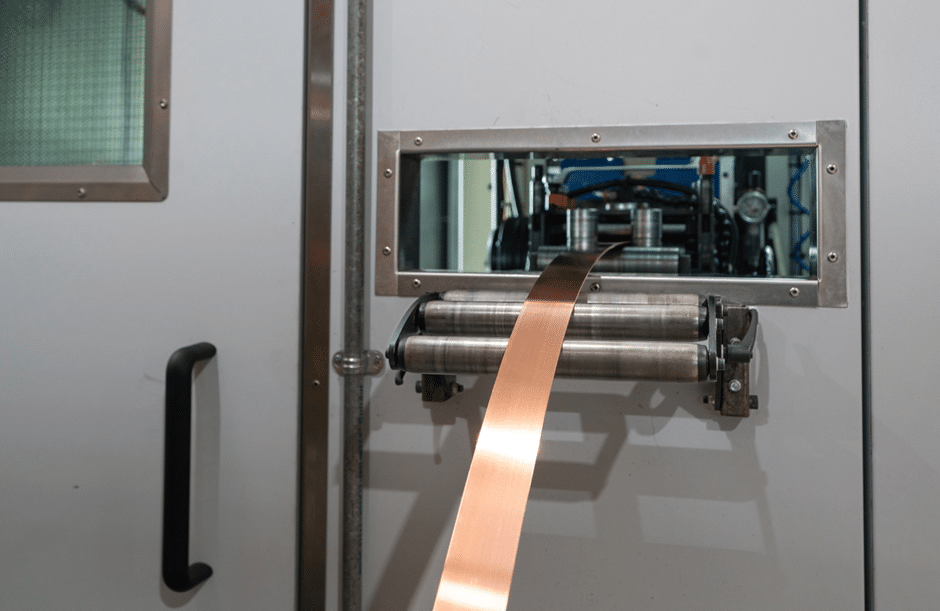

Flat springs feature a flat design, hence the name; they don’t feature a coiled design like that of extension springs or compression springs. The desired design is achieved by stamping flat metal material, which is frequently used in constrained or small areas.

Design and Functionality of Flat Springs

Due to their unique design, flat springs are ideal for many kinds of applications, as they are able to fit even into the tiniest space. Additionally, they are also available in all sorts of sizes and shapes, offering flexibility and versatility.

These springs are also known for their durability, as they can be made from high-quality materials, like stainless steel and high-carbon steel. Flat springs are long-lasting, so they’re able to resist wear and environmental factors. Not only that, but they are also able to maintain their shape even under repeated stress. This reliability in all industries is critical, as component failure can lead to safety issues or downtime.

Flat springs work by bending or flexing when force is applied. The material and design allow the spring to store energy through bending. When the force is removed, the spring returns to its original flat shape, releasing the stored energy.

Applications of Flat Springs

These springs come with a variety of unique characteristics and shapes, such as rectangular strips and curved shapes, which is beneficial to delivering accurate mechanical performance in applications with limited space. They provide a tailored fit for specific needs and are typically made from flat metal sheets. Stainless steel, high-carbon steel, and other premium materials are typically used in the design, which provides longevity, fatigue resistance, and shape retention under repeated load.

The load capacity and deflection of flat springs will depend on their material, thickness and overall design. They are designed to provide precise force and movement control in many applications, including:

- Aerospace: Perfect for the aerospace industry because it requires dependable and lightweight components.

- Medical: Flat springs are essential for maintaining accurate mechanical performance in restricted spaces.

- Electronics: Used to offer small spaces with stable electrical connections.

Why Use Flat Springs?

These springs are often required in tight spaces where traditional springs are not suitable; their compact and flat design allows efficient use of space. Flat springs are employed where precise force and movements are required, as they can be manufactured in a variety of sizes and shapes. Premium spring materials are used to manufacture these types of springs, providing durability and resistance to wear and environmental factors.

We prioritise your requirements throughout the design and manufacturing process to make sure that we deliver excellent products and services to all our customers.

We offer a range of flat springs, which include:

- Spring Nuts

- Clamps

- Spring Clips and contacts

- Tool holding clips

- Leaf springs

What To Consider When Choosing Flat Springs

There are several things you should consider when choosing flat springs:

- Material: Flat springs are available in various metals, so be sure to select one that suits your specific needs. Consider aspects such as corrosion resistance, strength, and load capacity.

- Size: These springs come in a variety of dimensions, even though they are generally small. Make sure to check the height, width, and depth for your application.

- Environment: Think about the conditions the spring will be exposed to, such as temperature or moisture, as these factors can influence material choice.

These are just a few factors to consider when selecting your flat springs, but these should be tailored to your chosen industry.

Why Choose European Springs as Your Flat Spring Supplier?

At European Springs and Pressings, we are experts in manufacturing the highest quality springs and pressings, as we’ve been operating for over 70 years. We are constantly striving for the best results, so we’re always looking for new solutions to enhance our manufacturing processes. We also utilise advanced machinery to produce high quality products. Due to our expertise and experience in the spring manufacturing industry, we are proud to be a prominent member of The Institute of Spring Technology and the Institute of Sheet Metal Engineering.

All our flat springs are manufactured carefully and with details by skilled engineers, no matter what type of springs you need, we are here to assist you in delivering springs based on your needs and requirements. We are proud on our quick turnaround times, meaning you’ll get your products delivered promptly.

At European Springs and Pressings, we’re proud to be one of the UK’s leading manufacturers of flat springs. Backed by decades of experience, our engineers are here to support you at every stage, from design to delivery. Explore our range of custom springs or get in touch with our team today, we’re happy to help with any questions or custom requirements.