In the world of manufacturing, every minute and every penny counts. As a trusted compression spring supplier, we work with businesses day in and day out to create solutions for their applications using a rounded approach that saves money and time. We uniquely offer an end-to-end approach, saving you from delays, errors, and the higher costs typically associated with sourcing from multiple suppliers.

By offering a fully in-house solution, European Springs & Pressings can help businesses streamline production, reduce costs, and maintain the highest quality standards – all under one roof.

Choosing the Right Compression Spring Manufacturer

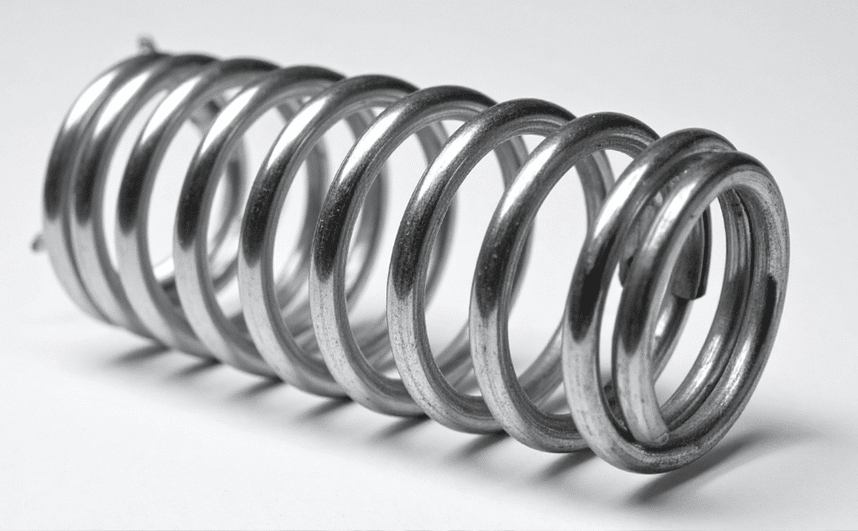

Compression springs are one of the most popular types of springs, serving countless uses in machines and devices. They’re typically known for providing reliable resistance, shock absorption and for managing loads effectively. From medical devices like surgical instruments and syringes to ballpoint pens and door locks – compression springs are everywhere.

Automotive: Used in suspensions, shock absorbers, and braking systems.

Electronics: Found in switches, connectors, and battery contacts.

Industrial Machinery: Ensuring smooth operation in presses, pumps, and valves.

Aerospace and Medical Devices: Where reliability, precision and the right materials are crucial.

Choosing the right spring, and having it made by the right manufacturer, can have a big impact on the efficiency, durability, and cost-effectiveness of your products.

How Does In-House Manufacturing Lower Costs?

Many suppliers only handle one or two stages of spring production, such as coiling or assembly, which often forces businesses to juggle multiple manufacturers. This creates extra handovers, shipping costs and risks of error.

A fully in-house process avoids these issues. With design, tooling, prototyping, production, and assembly under one roof, manufacturers benefit from:

- Fewer delays – no waiting for parts to be shipped between suppliers.

- Lower costs – reduced logistics and handling fees.

- Shorter lead times – faster development cycles and quicker delivery.

- Better quality – a single chain of responsibility with full product traceability.

For businesses producing at a high scale, those benefits quickly add up to significant time and cost savings.

Global Resources: Strengthening Local Manufacturing

Another factor that helps keep costs down is access to wider resources. Being part of the internationally recognised Lesjöfors Group, we’re part of a global network of spring specialists. This makes us not only specialists in compression springs, but also means we can supply over 12,000 items, which can be found in our stock spring catalogue.

So, whether you need a bespoke project, or something on a larger scale – we can help. If you require both a one-off customised product and high-volume quantities, you only need to work with one supplier, which is a rarity in this industry.

Why Choose a Full-Service Compression Spring Manufacturer?

When choosing a compression spring supplier, reliability is everything. A full-service manufacturer has clear advantages:

- Expert guidance: Engineers who understand both spring design and your industry requirements.

- Advanced technology: Coiling, stamping, and laser-cutting equipment for precise, consistent results.

- End-to-end quality assurance: ISO 9001 certified, with rigorous checks at every stage to ensure reliability.

- Collaboration: Consultation at every stage, so you know what’s going on with your project.

With fewer moving parts in the supply chain, businesses can stay confident that their compression springs will meet specifications, perform as expected, and arrive on time.

Design Matters: Getting the Right Compression Spring for Your Application

Saving time and money isn’t just about choosing the right manufacturer. The performance of a spring depends on many factors like wire diameter, material, and even the surface finish. In high-volume production, small design details can make a substantial difference to efficiency and cost.

A spring that isn’t correctly designed for its application can lead to premature wear or failure and inconsistent performance – especially in sensitive applications like electronics or medical devices.

To get it right from the start, here is a checklist of things to consider:

- Materials

Different materials perform better under different conditions. Stainless steel compression springs, for instance, are especially suited to industries that are subject to corrosion or fluctuating temperatures. Materials like beryllium copper, on the other hand, have great thermal and electrical conductivity, which might be more important for your application.

- Surface treatments & finishes

Coatings such as zinc plating can extend the life of springs by improving resistance to corrosion, fatigue, and wear. The right finish can reduce long-term maintenance costs significantly.

- Spring dimensions

Wire diameter, coil pitch, and overall length all influence how much load a spring can handle and how it works under compression. Precision at this stage ensures consistent performance in high-volume applications.

With decades of experience handling compression springs, we can guide you through these considerations and more when designing your springs.

Next Steps

If your business is looking to cut costs and streamline production, European Springs & Pressings offers the resources and expertise to help.

Start saving time and money in high-volume production with us today – get in touch with our team.