We frequently work with clients operating in extreme conditions and therefore require components that can last. From intense corrosion to severe temperatures, springs need to be able to handle these unique demands, performing reliably and safely at all times.

Many industries face these kinds of challenges, whether it’s aerospace, marine, or high-pressure manufacturing systems. The wrong spring material or design can mean costly downtime, safety risks, or system failure. For engineers, we can help you with selecting the right combination of materials, coatings, and specialist design, so that your springs perform exceptionally in even the harshest settings.

Why Extreme Environments Matter for Spring Design

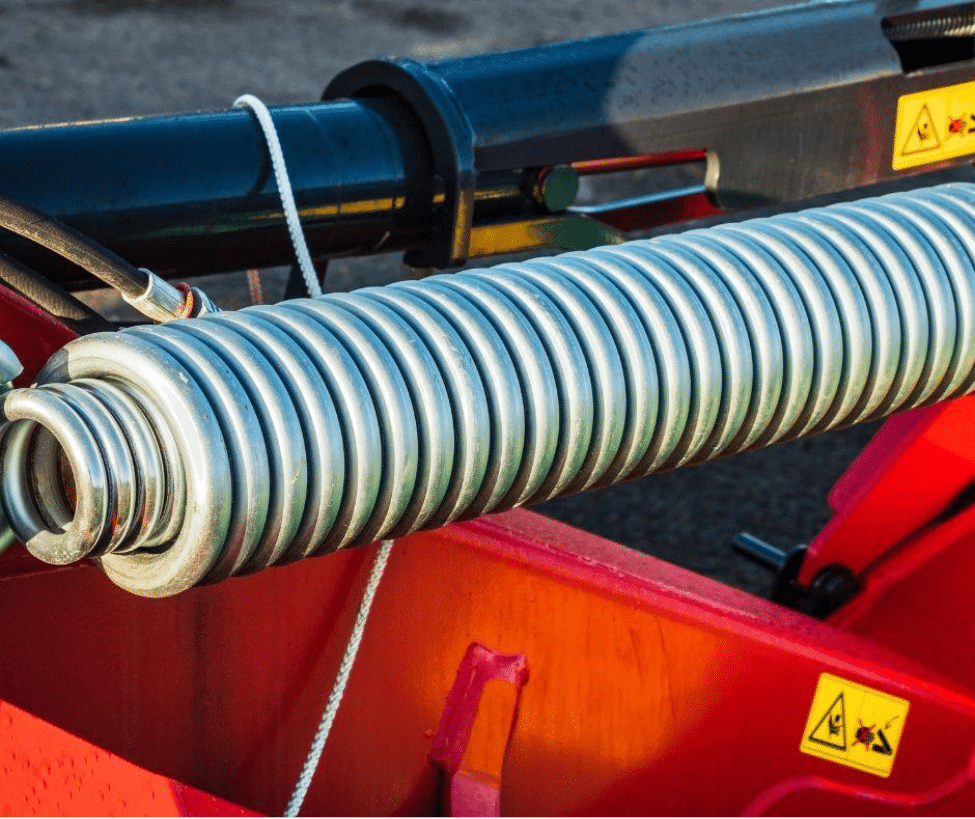

Springs undergo repetitive stress cycles, and their performance depends on the environment they operate in. Understanding how different kinds of extreme conditions impact springs is crucial for engineers:

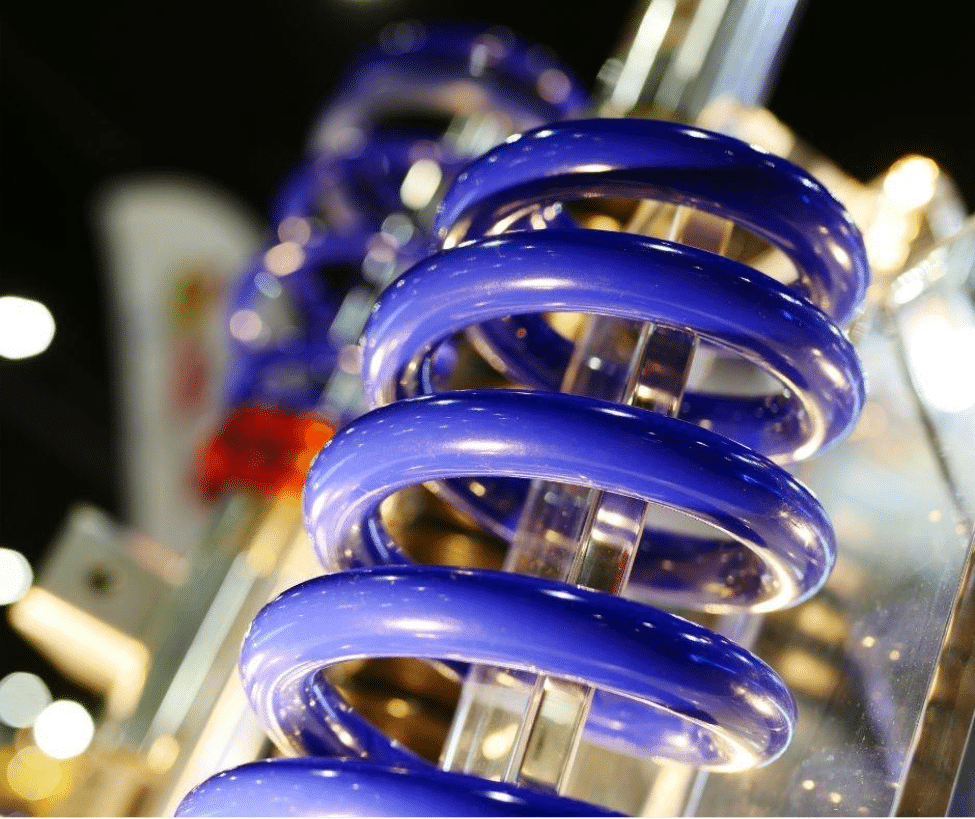

- High heat can reduce the strength and stiffness of certain materials, causing permanent deformation. Springs in automotive applications are often exposed to these risks, especially within areas of the engine and exhaust systems.

- Low heat makes materials brittle and prone to cracking, making it essential to select materials that maintain their ductility and flexibility in cold environments. Medical devices experience both extreme high and low temperatures, springs need to be able to maintain their core properties under sterilisation.

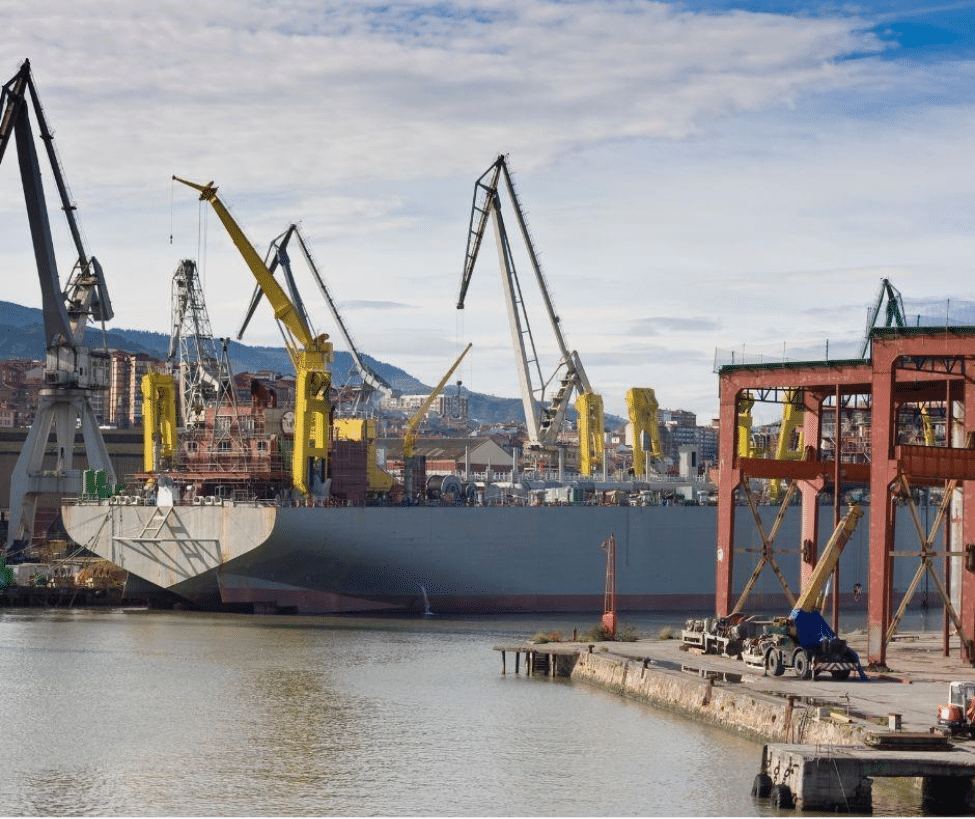

- Corrosive atmospheres such as seawater, chemicals, and industrial gases eat away at metals, causing springs to corrode and weaken. The marine sector is particularly known for requiring components that are corrosion-resistant due to seawater exposure.

- High-pressure systems create stress concentrations that can cause springs in the wrong design or material to deform or break. Many industries are subject to high pressures, including industrial manufacturing and oil and gas.

When you expose your springs to any of these conditions, choosing the wrong design or production method can compromise safety and reliability.

Material Selection for Extreme Conditions

Choosing the right base material is the most critical step when designing springs for demanding conditions. At European Springs & Pressings, we pride ourselves on offering an extensive selection of materials for our springs and metal stampings:

- Stainless Steel: Good balance of corrosion resistance and strength, widely used in marine and industrial environments. We offer a variety of stainless steel options, including those specifically designed for anti-corrosion, high temperatures, and anti-magnetic.

- Inconel: A nickel-chromium-based superalloy with exceptional resistance to heat and oxidation. Inconel is a popular choice for aerospace, gas turbines, and power generation.

- Phosphor Bronze: A copper-based alloy containing copper, tin, and phosphorus. The latter material gives springs and pressings made from this metal protection against wear and corrosion. Typical sectors where Phosphor Bronze is used includes electronics, automotive, and mechanical industries.

- Elgiloy: A cobalt alloy that contains copper, nickel, chromium, and molybdenum. It is known for its corrosion and fatigue resistance yet is still able to be formed into complex designs and shapes meeting unique specifications.

The right material depends on the balance between temperature, pressure, and environmental exposure. This is where consulting with experienced spring specialists adds real value.

Protective Coatings: Extending Spring Life

Even the strongest alloys need additional protection when exposed to corrosive or extreme environments.

Zinc-based coatings are the most common choice for extending service life, in particular electro-galvanising. This produces a smooth, even layer, and to improve corrosion resistance further, components are treated with bright chrome or yellow chrome. Zinc- and Bezinal-coated wire provide a cost-effective option for larger components, particularly where full stainless steel would be excessive.

For higher levels of protection, advanced systems such as Delta-Seal and Magni 565 give excellent corrosion resistance with no embrittlement risk. Epoxy coatings create a tough, durable surface that also performs well in harsh conditions.

In more specialised cases, Teflon offers outstanding chemical resistance and low friction across a wide operating range from –190°C to +260°C.

Corrosion resistance varies depending on coating thickness, porosity, adhesion, and pre-treatment. We conduct laboratory salt spray tests to provide general guidance, but real-world performance always depends on the specific environment and application.

To learn more about the protective coatings available at European Springs & Pressings, please consult our spring catalogue.

How European Springs Supports Engineers

At European Springs, we don’t just provide standard stock products, we partner with you to develop an application-specific solution. Our expertise includes:

- Custom material selection for high-performance alloys.

- Precision manufacturing of springs, pressings, and wire forms for demanding industries.

- In-house testing and prototyping to ensure reliability under tough conditions.

- Quality assurance at every stage, using ISO-9001 certified processes.

Across many industries, we provide components that not only function but also perform in the toughest environments.

Ready to Design Springs That Last?

Extreme environments need more than just standard solutions. If you’re working on a project that requires springs capable of withstanding heat, cold, corrosion, or pressure, our team is here to help.

Contact European Springs & Pressings today for a technical consultation, or to speak to a specialist about your project requirements.