Choosing the material when designing a compression spring is very important. Whether you’re building on a large scale or at a small scale, material selection is crucial to ensure that the spring performs well and is long-lasting.

One of the most frequently asked questions is what materials work best for compression springs. Well, there isn’t necessarily a right or wrong answer because it all depends on what they’ll be used for, and where they are going to be used.

What Are the Common Materials Used for Compression Springs?

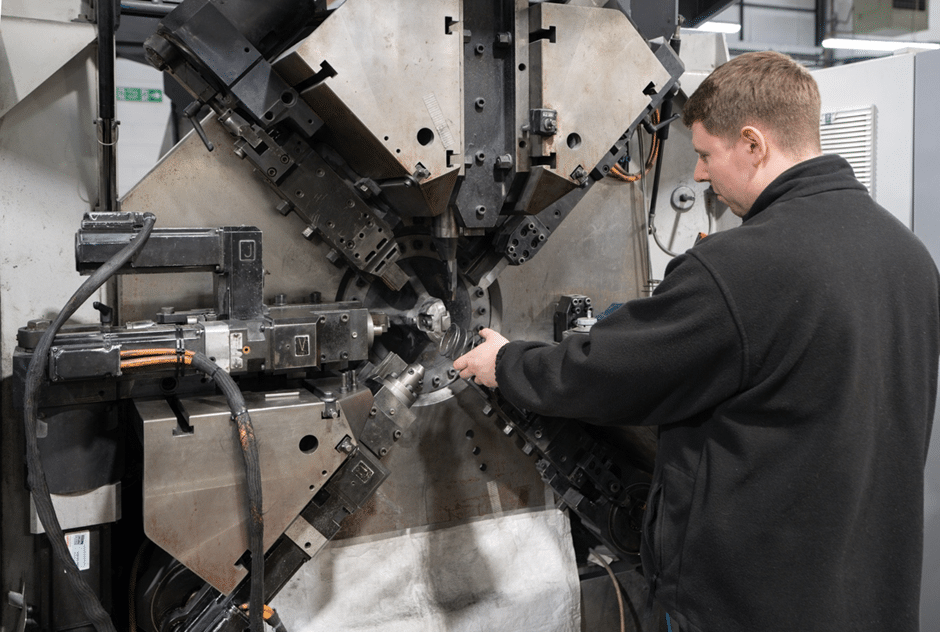

As a compression spring manufacturer, we can manufacture springs from a variety of materials, each offering unique properties that may be better suited for specific applications. These are the commonly used materials:

- High Carbon Steel: One of the most widely used materials for general-purpose springs, as it is strong, durable, and cost-effective, making it an ideal choice for everyday applications.

- Stainless Steel: Stainless steel is ideal when corrosion resistance is needed. It’s more pricey than high-carbon steel but is perfect for environments that may expose the spring to moisture or chemicals.

- Copper Alloys: These materials have high electrical conductivity and resistance to corrosion. They are ideal for use in electronics and sensitive equipment.

- High-Performance Alloys (Inconel, Hastelloy): Ideal for components that are going to be placed where conditions are extreme, such as high temperatures or harsh chemical environments. They’re often used in aerospace, automotive, and energy applications.

Why Choose Stainless Steel for Compression Springs?

Stainless steel is one of the most popular materials for compression springs, particularly in challenging environments. If you’re working in environments that involve moisture, chemicals, or high temperatures, stainless steel offers several advantages:

- Corrosion Resistance: Stainless steel is highly resistant to rust, which makes it ideal for outdoor, marine, or food-related applications where moisture is present.

- Strength and Durability: Stainless steel maintains its strength, even under repeated stress, which is crucial for applications where the spring is constantly in use.

- Temperature Resistance: Stainless steel can handle high temperatures better than carbon steel, making it a great choice for industries like automotive or aerospace, where the spring may be exposed to heat.

Choosing the Right Spring Material for Your Application

Selecting the right spring material is crucial, and it all depends on the specific needs and requirements of your project. Consider factors like corrosion resistance; will your springs be exposed to moisture, chemicals or harsh environments? If so, stainless steel and copper alloys are your best choice as they resist rust and deterioration over time, which is required for long-lasting performance.

Think about whether the springs are going to be used in electrical applications because some materials, like copper alloys, offer excellent electrical conductivity. If your springs are exposed to high temperatures, consider high-performance alloys because they are able to maintain their properties even under extreme conditions. Lastly, if you’re looking for springs to use in standard machinery that doesn’t face harsh conditions, then high-carbon steel is both cost-effective and a strong material that could be used.

Which Material Is Best for Different Industries?

Depending on the industry you’re working in, different spring materials will be necessary. For example:

- Medical: In this industry, stainless steel is often used for implants, devices, or surgical tools because it is resistant to corrosion and hygienic, as it is easy to clean.

- Electronics: Copper alloys, carbon spring steel or stainless steel are essential for springs in electronics, as they provide excellent electrical conductivity.

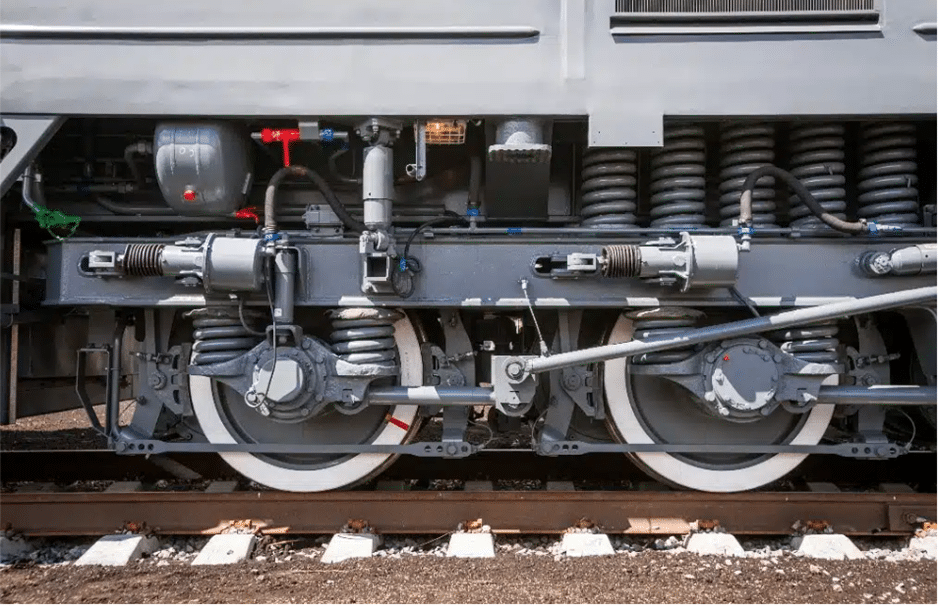

- Oil & Gas: Springs are crucial for oil and gas exploration, extraction, and transportation.

Choosing the correct spring material for your compression spring is super important to ensure optimal performance, longevity and safety in a wide range of different industries. The material should match your specific application.

At European Springs and Pressings, we can help find the right spring materials for all your needs. Whether you’re looking to find components for high-precision medical devices or custom spring solutions, our team of experts are here assist. If you need some guidance on what material would work best for your project, then feel free to contact us for advice.