With over 70 years of experience as suspension manufacturers, we create durable and reliable suspension springs. We’re committed to precise engineering and high-quality materials, ensuring your springs are long lasting and reliable.

Suspension springs are used to store and release energy, absorb shock, and maintain a consistent force between two contacting surfaces. They are typically found in the automotive sector thanks to their ability to absorb bumps on the road, enabling car manufacturers to deliver a smoother ride for their customers.

Whether you’re a global corporation needing a high-volume order of springs or working in a smaller niche industry requiring a custom solution, we can help.

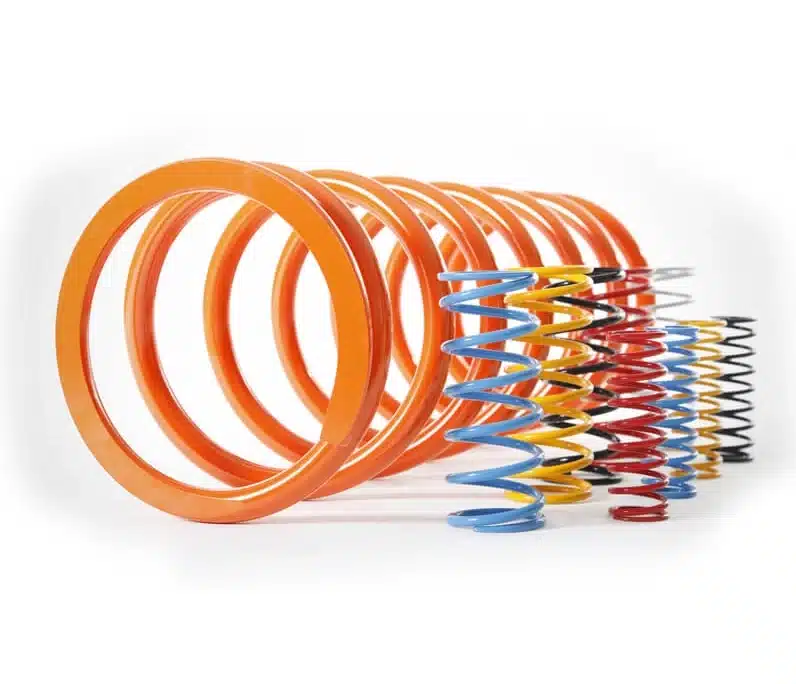

We manufacture a range of suspension springs for the transport sector and beyond, including for motorcycling, touring and IndyCars. We’re able to produce small and large-volume suspension springs, including components that need to be made to unique specifications.

We pride ourselves on delivering tailored suspension spring solutions. Using advanced CAD systems and CNC machines, our engineers work with you to create springs optimised for your application.

When designing a bespoke suspension spring, we can tailor the:

Our suspension manufacturers are experts in theoretical modelling, assessing stress levels, and evaluating creep or fatigue performances, delivering an exceptional design service.

When creating suspension springs, we work with materials such as Nimonic, Hastelloy, Inconel, copper alloys, and steel.

As part of the international Lesjöfors Group, we have access to a wide selection of stock springs, on top of our made to order options. If you need a large-volume production, stock springs are a great solution for consistent, uniform springs made to the highest standard.

With rigorous quality assurance and in-house testing, we ensure every suspension spring performs exactly as intended.

In addition to our suspension spring manufacturing capabilities, we provide a complete range of supporting services to ensure your project runs smoothly. This includes:

All our processes are ISO 9001 certified, ensuring consistent quality, full traceability, and complete confidence in every suspension spring we manufacture.

We also produce compression springs, torsion springs, tension springs, and flat springs, allowing you to source all your components from a single supplier.

For further information or queries as leading spring manufacturers we would be happy to discuss your requirements in more depth, we encourage you to contact us.

Whilst they’re most commonly found in cars and other vehicles, suspension springs serve a range of purposes across many industries:

We work with a diverse range of steels, copper and titanium alloys, as well as super alloys, such as Inconel, Hastelloy and Nimonic, that are especially resistant to elevated temperatures and corrosion.

Choosing the right type of suspension spring depends on several factors, including load requirement, operating environment, mounting, finishes, and dimensions.

While compression springs and torsion springs are used in a wide variety of applications, suspension springs are designed specifically for heavy load bearing and shock absorption, making them larger, stronger, and more durable. Our engineering team is available to guide you through these considerations.

Yes. All our suspension springs are manufactured under ISO 9001 standards and undergo strict quality control and testing before dispatch.

Here is an inclusive list of the main sectors and applications where Suspension Springs improve designs and make a positive difference.