We are a leading supplier of stock and bespoke energiser springs that are built to last. For decades, we’ve been working with industry-leading companies providing spring energised seals for a range of applications using high-quality materials and innovative technologies.

With rigorous quality checks, ISO 9001-certified processes, and a team of engineering experts, we create energiser springs that you can rely on even in the harshest conditions.

Energiser springs are typically used to address the load limitations of a polymer seal jacket. While polymers provide appropriate sealing, they often lack consistency in load distribution.

A spring-energised seal works by being placed in a seal cavity where the spring and seal lips are compressed. This compression allows the lips to expand outward, increasing flexibility and providing reliable sealing even in motion.

Energiser springs come in various designs; each tailored for specific applications and performance characteristics. Browse all the springs we manufacture and find the right energiser spring for your needs:

‘U-shaped’ springs designed to provide clamping, holding or tension force. They’re often found in automotive clips, electrical connectors and fastening systems.

Coil springs formed in a circular loop that provide constant radial tension. Most commonly used in oil and shaft seals.

Springs used in fencing or rail systems to maintain tension in the top rail or wire, absorbing movement to keep the rail tight.

Due to their wide range of general uses, this range of springs is a highly versatile addition to any application, able to work effectively in a wide range of devices and machines such as valves, electric switches and as components in door locking mechanisms.

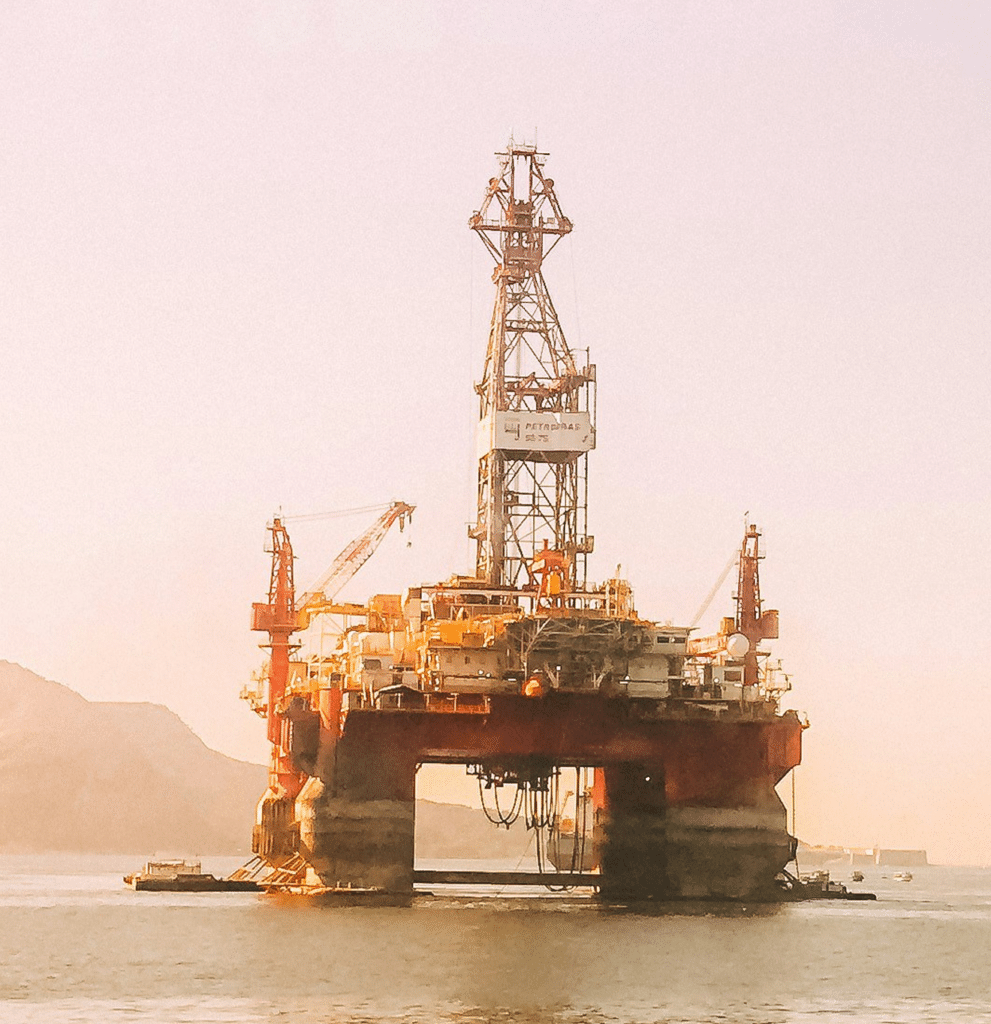

For the oil and gas industry, energiser springs are used for:

Find out more about how our springs are used in the oil and gas industry

In the medical field, energiser springs provide precise force for:

Find out more about how our springs are used in the medical industry.

We’re a trusted spring manufacturer by many, here are just a few reasons to choose us:

Selecting the right energiser spring involves many factors, including material compatibility with environmental conditions, assessing load requirements, sealing applications, seal geometry and installation space to recommend the best energiser spring for your specifications. For expert advice on energiser springs, please request a quote.

We have a range of spring materials available, including:

This all depends on the application, the environment, and any other relevant factors. For example, garter springs are suitable for simple, uniform radial pressure around a shaft. If you’re unsure on the best spring for your needs, please reach out to us for guidance.

Energiser springs work in a range of temperatures depending on the material. Stainless steel is suitable for general industrial applications, while high-performance alloys such as Inconel, Nimonic or Hastelloy are better suited to extreme temperatures, both high and cryogenic.

Yes. We specialise in bespoke energiser springs tailored to your specific requirements. When requesting a quote, please provide us with any details such as space constraints, sealing requirements, environmental conditions and load specifications, and our engineering team can design a spring that meets your needs.

Here is an inclusive list of the main sectors and applications where Energiser Springs improve designs and make a positive difference.