Medical Stampings & Medical Component Manufacturers

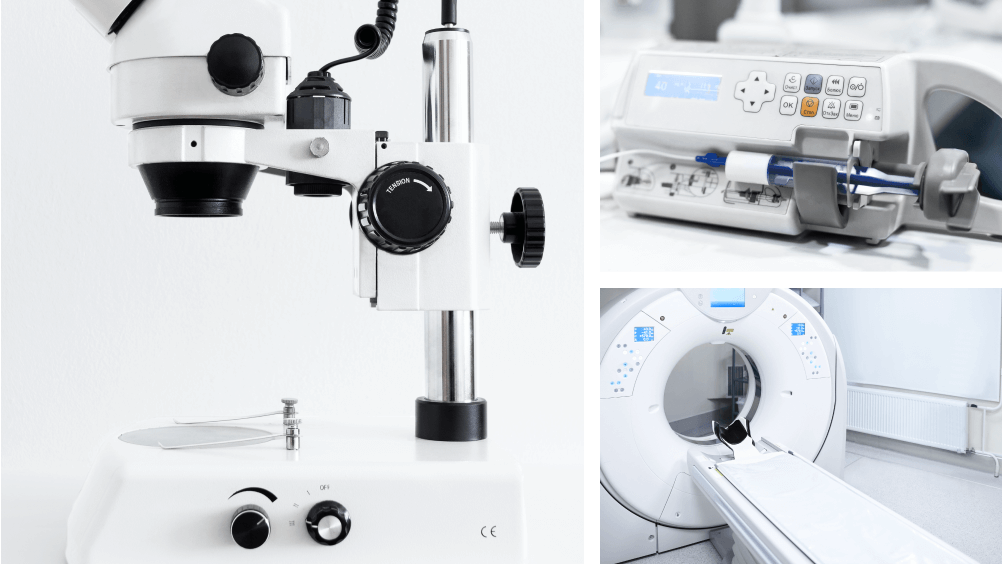

We, at European Springs & Pressings, manufacture and supply a wide range of medical stampings for the healthcare industry. We are proud to say that our products have been able to benefit the sector.

Medical components have become increasingly necessary, and we have also been contributing to the healthcare industry by stepping up production in order to meet increased demand from our customers and manufacturing products for catheter clips, ventilators, filters (for breathing apparatus) and protective visors.

Medical Stampings for the Healthcare Industry

Medical components need to be designed and manufactured with the highest quality in mind and via the latest processes and technology, considering the whole sector depends on reliable products to aid patients and advance research.

Many different springs and stampings are used in the healthcare industry, including precision stampings and gas and compression springs. While medical engineering requires the use of different components, they still share similar features, such as the need to comply with strict industry standards.

Common Gas Springs Applications in the Medical Industry

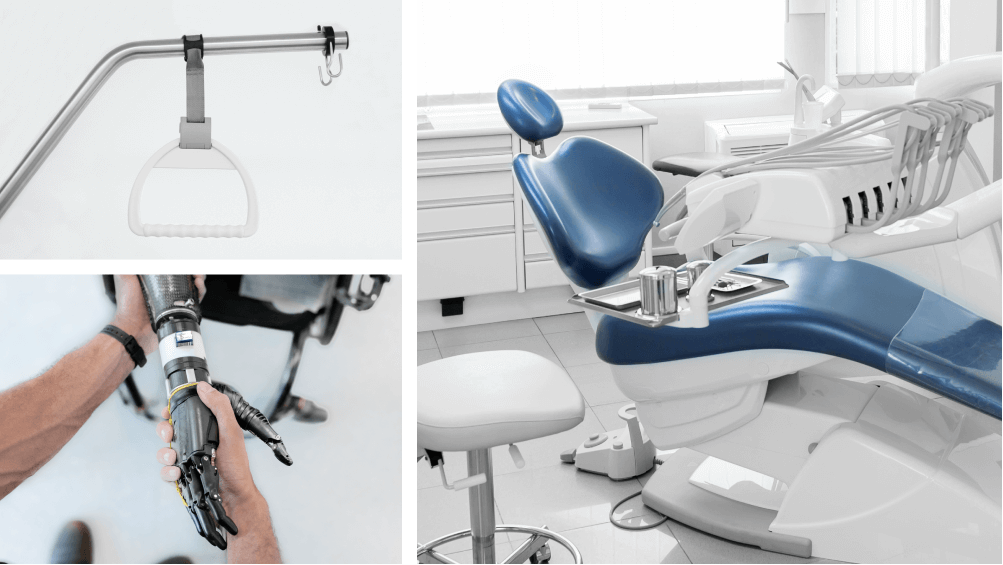

As gas springs manufacturers, we are aware that these types of springs are one of the most sought-after in the sector, as they have a wide range of applications and provide healthcare with a wealth of benefits. Take a look at some of the most popular uses for gas springs and gas struts in this sector:

- Flow control valves

- Healthcare beds

- Physiotherapy beds

- Pressure regulators

- Patient trolley systems

- Positive pressure ventilator

- CPAP machines

- Robotic-assisted surgery

Get in Touch for Medical Stamping & Component Manufacturing

We have over 70 years of experience in manufacturing including being medical component manufacturers, and we’ve been providing springs and pressings to healthcare customers for many years.

The need for these medical components has never been so important as it is at the moment, so we’re capable of designing and products that are suitable for use in sterile environments and be medical components manufacturers that always achieve the high performance you’re looking for.

Don’t hesitate to get in touch with European Springs & Pressings to learn more about how we can help you during these challenging times. You can also browse our spring catalogue to find the right medical springs for your medical components.