Springs in Construction

Construction is a vast and fast-paced industry with a never-ending variety of projects, each requiring thousands of various components to complete a given task. From big projects to small, there is a spring designed to suit all jobs.

Here at European Springs, we provide a wide selection of springs for all industrial applications; regardless of your project, we have a spring especially designed for the job. Take a look at some of our options below.

Compression Springs

Compression springs are among the most common types of spring available due to their energy storing properties. When the coil is pressed, it stores the energy until it is released: ideal for everything from trampolines to mattresses, and shock absorbers. Whereas an extension spring is designed to pull things together, compression springs are designed to keep things apart.

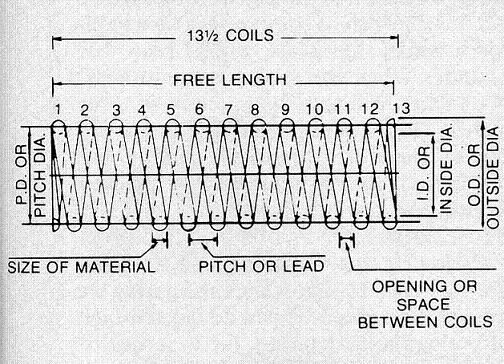

In order to make the spring dependably solid, the pitch, or ‘distance between coils’ must be kept the same throughout the wire. This can be a problem if done manually, using a lathe. However, our highly-calibrated machinery at European Springs is specifically designed to keep the pitch consistent, and we can specify the length of the pitch in the design process.

What Are They Used For?

Because compression springs are so versatile, they are used in a whole host of industries, ranging from automotive, electronics, medical equipment and commercial sectors.

Because compression springs have a variety of applications, there are a number of factors that need to be considered before construction, such as the spring rate, wire diameter, number of active coils, solid height and the stress level.

Take a look at the following video to learn how we manufacture compression springs:

Torsion Springs

Torsion springs work by storing energy through being twisted, which creates torque. This mechanical energy can then be stored and released on demand. The really impressive part about torsion springs is that they release the same amount of energy that was put in. The formula goes, ‘Torque = Force x Leg Length’ and can be applied to torsion springs of any size.

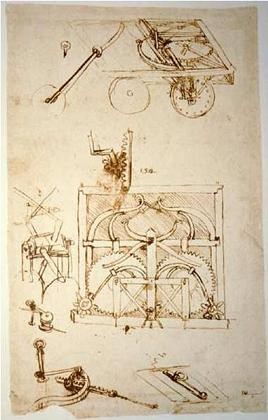

Leonardo Da Vinci was famous for his hidden inventions, and in 1478 at the age of 26, he created what is considered by many to be the first automobile using a combination of torsion springs. Even more impressive is the fact that Da Vinci’s mini-car did not simply move forward on its own; it also had steering capabilities.

You can read more about Da Vinci’s automobile on How Stuff Works, which explains how the model is steered ‘by rotating the wheels opposite of their intended direction‘. You can also view some other inventions Da Vinci designed which helped shape the future.

What Are They Used For?

You can find torsion springs in a host of useful items and mechanisms, from mousetraps and garage doors to siege weapons. The standard model for a torsion spring is, of course, the common mousetrap, but they can also be found in the housings of certain automatic door systems. With the exception of electronic doors, the counter-balance device in most garage doors relies on the backward pull of the torsion springs in the hinges.

Another example from antiquity would be the Mangonel, an ancient Greek catapult that used great torsion springs in a wooden frame to fling huge missiles at enemies. In order to achieve a torque strong enough to hurl giant rocks, the ancient Greeks would have had to calculate things like wiring, length, and pitch, all proportional to the weight of their ammunition.

Things have changed a bit since those times…take a look for yourself!

Tension Springs

Tension springs operate when a pulling force is applied to them; as they endeavour to retain their original state, tension is created. In their resting state, all the coils of a tension spring will be touching and will return to this state once the force being applied is slackened or wholly ceased. In this way, tension springs are considered to perform a diametrically opposed function to compression springs.

Under a state of equilibrium, a tension spring operates under all forces at a value of zero. When the sum of all forces is not zero (when a third-party impulse is imparted) the spring is subject to Newton Third’s Law, acting and reacting at the same time.

Owing to Hooke’s Law, the spring will only operate up to the limit of its elasticity, and therefore it is important that tension springs are manufactured to withstand the necessary amounts of tension for a given task. As the majority of tension springs are manufactured with looped or hooked ends, they can only feasibly operate up to 60% of their permitted tension. At European Springs, the manufacture of loose looped, tapered ends allows our tension springs to operate at maximum capacity.

What Are They Used For?

Tension springs can often be found in garage doors and trampolines, as well as a wide range of other products. They are predominantly made of steel or stainless steel, due to the increased elasticity of steel over other metals, such as copper, and the greater values of pressure and pounds per square inch beyond aluminium. These features mean that a steel spring can bear greater tension before reaching its elasticity limit, recover its original shape quicker, and it requires roughly three times less exertion to produce the same force as an equal aluminium spring.

Other Springs

Aside from the three main categories of compression, torsion and tension springs, there are a whole host of other springs, such as clock springs, disc springs and die springs that perform vital tasks.

Clock springs take their name from their most common usage, as a component in clocks and watches. Not to be confused with the similarly named clocksprings – used in driving – a clock spring is predominantly made of stainless steel, though here at European Springs we are happy to make them to personal specification.

The spring acts as a torsion spring, though instead of the traditional pressure under which the spring is placed, it rotates in a circular motion, revolving around the axis of an object, thus pushing the imparted impulse onto another object via the outer rotating edge of the spring. As such, clock springs are made of flat wire, as opposed to round wire, for greater surface contact with the pushed object, providing maximum distribution of force.

Take a look at our short video of how we design clock springs:

The versatility of the disc spring means that there is a near-unlimited amount of stacking combinations available. You will most commonly find disc springs in the clutch and braking systems of automobiles.

Take a look at how we manufacture disc springs:

The main purpose behind die springs is to take the weight of something that may become heavier over time – for example, perforated or absorbent material. As such, die springs are often used in press tools, moulds and die-casting, as repeated pressure is applied to exert a force. We can provide die springs with both open and closed ends, as well as colour coding according to strength.

As experienced spring manufacturers, we can help in designing the ideal spring for your construction project. If you would like to find out more information about our springs, or for further information on our other products, get in touch with us today by calling 0208 663 1800 or emailing info.bec@europeansprings.com. Our friendly team of experts are happy to help.

[button url=”https://www.europeansprings.com/contact/” class=”scbutton”]Get in Touch[/button]