The manufacturing sector is driven by innovation, technological advancements, and skilled professionals, and it’s evident that nurturing a new generation of talent is vital for its continued success. This is where manufacturing apprenticeships come into the picture.

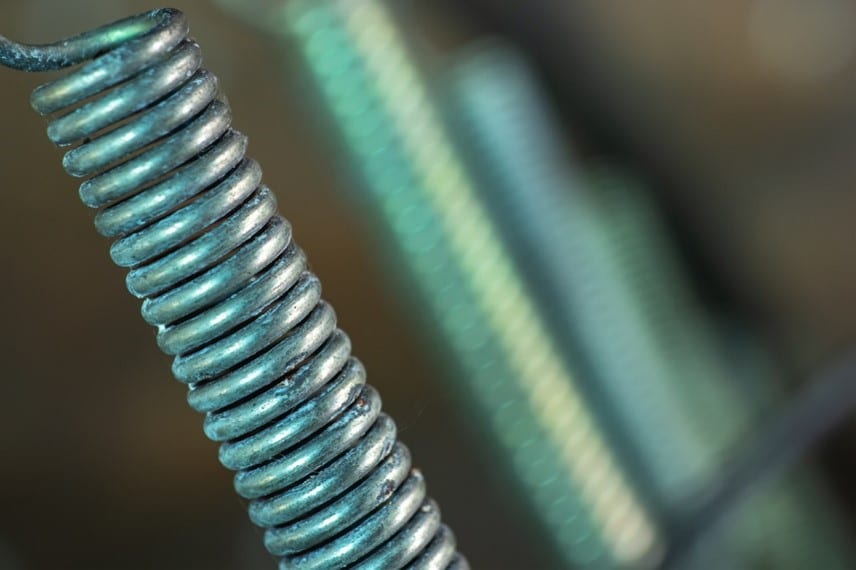

At European Springs & Pressings, we understand the significance of apprenticeships in shaping the future of manufacturing. With decades of experience as one of Europe’s leading spring and pressings manufacturers, we have witnessed firsthand the transformative impact of apprenticeship programs on individuals and the industry.

So, we’d like to shed light on the critical role manufacturing apprentices play in driving innovation, meeting industry demands, ensuring a sustainable workforce and hopefully encouraging a new generation of spring manufacturers to join this exciting industry.

Addressing the Skills Gap

The skills gap refers to the disparity between the current workforce’s skills and the skills required by modern manufacturing industries. Manufacturing apprenticeships play a crucial role in addressing this skills gap within the sector. This is because, as technology advances and new processes emerge, there is an increasing need for a highly skilled workforce that can adapt to these changes and drive innovation.

For example, apprenticeship schemes provide hands-on, practical training that equips individuals with the skills and knowledge needed in the manufacturing industry. Rather than relying solely on theoretical education, apprentices gain valuable experience by working alongside experienced professionals, operating machinery, and participating in real-world projects. This practical training ensures that apprentices develop the necessary skills to meet the industry’s evolving demands.

In addition, these training programs aren’t limited to entry-level positions and can be used to upskill and reskill existing workers. By offering apprenticeship programs to existing employees, companies can address skill gaps within their own workforce and ensure that their employees remain updated with the latest technologies and processes.

Workforce Development

As mentioned, apprenticeships aren’t limited to those beginning their career in the manufacturing industry but are often used to nurture a skilled and adaptable workforce. This is because these programs allow individuals to gain practical, industry-specific training and experience, enabling them to develop the essential skills needed to excel in the manufacturing sector. By combining on-the-job training with classroom instruction, apprenticeships create a seamless pathway for individuals to acquire the technical competencies, problem-solving abilities, and teamwork skills necessary for success.

Manufacturing apprenticeships are often favoured over degrees in the same subject because of the practical knowledge and experience trainees get. Of course, this hands-on experience is fantastic for new starters, but it’s also necessary for those already years into their careers, as it reminds them not to fall into bad habits and keeps their knowledge fresh.

Improved Productivity

It may come as a surprise, but manufacturing apprenticeships can actually have a positive impact on workplace productivity in several ways, for example:

- Skill Development. Apprenticeships focus on providing practical, hands-on training that directly relates to the specific needs of the manufacturing industry. This training enables them to contribute effectively and efficiently to various tasks and projects, enhancing overall productivity.

- Knowledge Transfer. Apprenticeships promote the transfer of knowledge from experienced professionals to apprentices. As a result, apprentices quickly become proficient in their roles, accelerating the learning curve and improving productivity.

- Fresh Perspectives and Innovation. Manufacturing apprenticeships often attract young and enthusiastic individuals who bring fresh perspectives and innovative ideas to the workplace. Their exposure to the latest technologies, methodologies, and industry trends during their training allows them to offer unique insights and creative solutions that can help streamline operations and embrace technological advancements.

Building Strong Communities

As discussed, there are many benefits of manufacturing apprenticeships, but one of the primary reasons they’re so popular for companies in this sector is because of the strong communities they help to build. Manufacturing apprenticeships play a vital role in building strong communities by fostering economic growth, creating job opportunities, and empowering individuals within the local workforce. These training programs provide valuable pathways for individuals to enter the manufacturing industry, allowing them to develop in-demand skills and secure stable employment. When companies invest in apprenticeships, they contribute to local job creation, stimulating the economy and reducing unemployment rates.

In addition, as apprentices gain practical experience and knowledge, they become valuable assets to the community, both socially and economically. This is because their newly acquired skills benefit the manufacturing sector and extend to related industries, further bolstering the local economy.

Apprenticeships at European Springs

Here at European Springs, we’re committed to helping the wider industry by investing in the younger generation and developing our apprenticeship schemes. We offer a range of apprenticeships that provide valuable training and career opportunities within the manufacturing industry. We have designed these programs carefully, ensuring they equip individuals with the skills, knowledge, and experience necessary to excel in various roles within the company.

If you’re interested in working with leading spring manufacturers in this ever-changing industry, we’d love to hear from you. Please take a look at our apprenticeship vacancies and don’t hesitate to get in touch for more information; a member of our team will be more than happy to help.

The Aircraft Interiors Expo (AIX) is an annual event focused on the latest developments and innovations in aircraft interior design, technology, and equipment, so as

The Aircraft Interiors Expo (AIX) is an annual event focused on the latest developments and innovations in aircraft interior design, technology, and equipment, so as