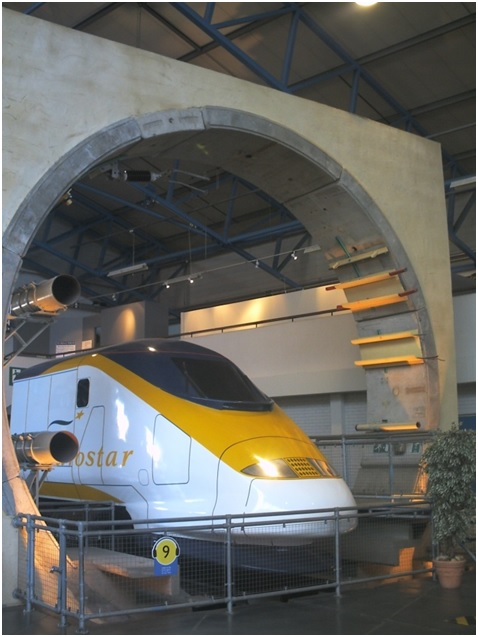

The Channel Tunnel is one of the largest engineering projects ever undertaken here in the UK. In total, the project took more than five years to complete and involved a collaboration between over 13,000 workers from England and France.

Here in the first instalment in our new series on great engineering achievements, we take a closer look at the revolutionary feat of engineering that is the Channel Tunnel.

A proposal to build a tunnel under the English Channel was first put forward back in 1802, by the French mining engineer Albert Mathieu. However it was not until the 1830s that the first geological and hydrographical surveys were conducted on the channel between Calais and Dover.

In the following decades a number of further proposals were put forward, however these ultimately failed to come to fruition due to a variety of factors, such as political discord and financial problems.

Then in 1981, it was agreed between the French president Francois Mitterrand and British Prime Minister Margaret Thatcher that a link across the English Channel would be mutually beneficial, and a working group was established to explore a privately funded project.

In 1985 proposals for the scheme were formally invited. Four proposals made the shortlist and these included a variety of innovative designs, including a suspension bridge and a road tunnel. However it was a proposal consisting of two one way rail tunnels and a service tunnel, presented by a Franco-British Consortium known as the France-Manche-Channel Tunnel Group, that was finally accepted.

Construction

The construction of the Channel Tunnel, which began in 1988, was a monumental task. In total 11 tunnel boring machines (TBM’s), each of which weighed 1,100 tonnes, were required in order to completed the excavation for the tunnel, and many of these were built specially for the project.

Excavation began simultaneously on both the British and French coasts, with the finished tunnel meeting and connecting in the middle.

This tunnelling presented a major engineering challenge, not least because underwater tunnels face the risk of major water inflow due to pressure from the sea above.

Completion

In total, the Channel Tunnel cost a staggering £4.65 billion to build and after years of hard work, was officially opened on the 6th May 1994.

The Channel Tunnel has now been helping passengers traverse the English Channel in only 35 minutes for over twenty years.

Following its completion the Channel Tunnel was also named one of the seven wonders of the modern world by the American Society of Civil Engineers.

Here at European Springs we appreciate great engineering and many of our products such as our high quality disc springs are used for a variety of applications within the engineering field. For more information about our range of products and the services we offer, please don’t hesitate to contact us today by giving us a call on +44 (0) 208 663 1800 and a member of our friendly team will be happy to help you with your enquiries.

European Springs